,一张提供开箱体验的护肤品包装的图片_1e7f8286-a0e2-49fd-b36a-4755c105449c.webp)

Where to Source High-Quality Skincare Packaging Caps: A Complete Buyer’s Guide to Quality and Standards

Content Menu

● Why Skincare Caps’ Material Selection Matters for Your Skincare Brand

● Where Quality Meets Engineering: Appearance Standards For Cosmetic Packaging

● Precision Surface Treatment and Printing for skincare caps

● Functional Reliability: The Zero-Leakage Guarantee for skincare bottles

● Conclusion: Your Destination for Premium Cosmetic Packaging

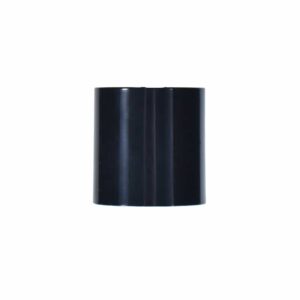

For brand owners and procurement managers, the biggest challenge isn’t just finding a closure, but knowing where to find skincare packaging caps that balance aesthetic luxury with industrial-grade reliability. A cap is the guardian of your formula. If the seal fails or the plating peels, the brand reputation suffers.

At AC Skincare Packaging, we provide premium solutions that meet the strictest global standards. This guide explains what you should look for when choosing a manufacturing partner.

Why Skincare Caps’ Material Selection Matters for Your Skincare Brand

When searching for a supplier, you must first identify the material that fits your product’s chemical composition and price point:

-

PP & ABS Caps: The go-to for durability and high-gloss finishes.

-

Acrylic (PMMA) Caps: Perfect for high-end “prestige” skincare lines.

-

Aluminum & Luxury Closures: Ideal for essential oils and premium serums.

Explore our full range of materials at www.skincarepkg.com.

Where Quality Meets Engineering: Appearance Standards For Cosmetic Packaging

Quality assurance starts with a visual and tactile inspection. We ensure every cap meets these four pillars:

-

Structural Perfection: No burrs, sink marks, or cracks. The shape must be full and intact.

-

Surface Purity: Surfaces must be clean, smooth, and free of scratches or dust.

-

Color Integrity: We use a 45° angle light test at a 30cm-40cm distance to ensure color consistency against the master sample.

-

Chemical Safety: All inner plugs and gaskets must be non-toxic and compliant with GB9687 and GB14944 (e.g., Potassium Permanganate consumption $\le 10mg/l$).

Precision Surface Treatment and Printing for skincare caps

Where many suppliers fail is in the longevity of the decoration. Our process includes:

-

Hardness Testing: All coatings must pass a 2H pencil hardness test.

-

Adhesion Excellence: We perform 3M tape tests and Cross-hatch tests (less than 5% peeling allowed) to ensure electroplating and spray-painting stay permanent.

-

Printing Accuracy: Pattern centering deviation is kept under 0.6mm, ensuring your logo looks perfectly centered every time.

Functional Reliability: The Zero-Leakage Guarantee for skincare bottles

A cap’s primary job is protection. To ensure this, our functional testing includes:

-

Vacuum Sealing Test: Bottles are placed in vacuum thermal drying ovens to ensure zero leakage.

-

Torque Control: We calibrate opening torque to 0.5N·m – 2.5N·m—tight enough for safety, light enough for the consumer.

-

Compatibility: We ensure the cap doesn’t bulge or loosen, and the liner remains resilient without dissolving into the lotion.

Conclusion: Your Destination for Premium Cosmetic Packaging

If you are wondering where to source reliable skincare packaging caps that pass rigorous QC, look no further than Skincare Packaging. We don’t just supply parts; we provide the engineering confidence your brand deserves.

Get a Professional Quote Today

Visit www.skincarepkg.com to view our latest designs or contact our team for a custom mold consultation. Email us at info@skincarepkg.com or WhatsApp us.